|

|

|

| |

| |

|

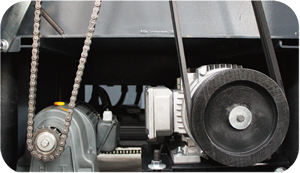

Variable speed infeed by inverter

suit for all types of finish required. |

|

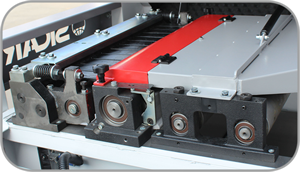

Cast iron table mounted on 4 heavy

pillars for excllent support and

accurent without any locking. |

|

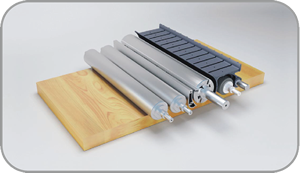

Spring-loaded pressure bars and

double out feed rollers design prevent

vibration of very thin work pieces

during thicknessing. |

|

| |

| |

|

| Professional electrical box. Frequency conversion control feeding speed. |

|

Independent module, bringing better strength and higher stability. |

|

Plc control + magnetic grid induction help to reduce positioning

time and high precision.

|

|

|

|

| |

|

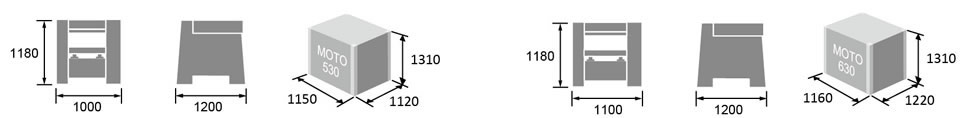

Pialla a Spessore |

Thicknessing Machine |

|

MOTO 530 |

MOTO 630 |

Larghezza max. lavoro |

Max. working width |

mm |

530 |

630 |

|

Diametro del albero |

Cutterblock diameter |

mm |

120 |

120 |

|

Spessore max. passata |

Max. cutting depth |

mm |

8 |

8 |

|

Velocità avanzamento |

Feed speed |

MT/1' |

5-20 |

5-20 |

|

Passaggio legno |

Max. working height |

mm |

300 |

300 |

|

Coltelli |

Number of knives |

p- mm |

4p-30*530*3 |

4-30*630*3 |

|

Velocità rotazione albero |

Cutterblock rotation speed |

g/1' |

4800 |

4800 |

Potenza motore |

3-phase motor power |

HP (KW) |

7,5 (5,5KW) |

7,5 (5,5KW) |

Potenza motoriduttore di sollevamento |

Power of the motorgear for rise/fall |

HP (KW) |

0,5 (0,33KW) |

0,5 (0,33KW) |

|

Potenza motore |

Feeder motor power |

HP (KW) |

1,0 (0,75KW) |

1,0 (0,75KW) |

|

Dimensioni del piano di lavoro |

Work table dimensions |

mm |

1050 x 532 |

1050 x 632 |

|

Min. lunghezza di lavoro |

Min. working lenght |

mm |

280 |

280 |

|

Peso netto |

Net weight |

kg |

810 |

875 |

|

Livello di potenza sonora nel posto operatore |

Sound power level at operator's site |

db |

82,2 |

82,2 |

| |

|

|

|

|

|

Dotazioni standard |

Standard Accessories |

|

MOTO 530 |

MOTO 630 |

|

Calibro registra-coltelli |

Knife-setting device |

|

● |

● |

|

4 coltelli per pialla |

4 pcs planing knives |

|

● |

● |

Sollevamento motorizzato del piano spessore |

Motorized thicknesing table lifting |

|

● |

● |

Rullo dentato sezionato |

Sectioned feeding roller |

|

○ |

● |

| |

|

|

|

|

|

Accessori a richiesta |

Optional accessories |

|

MOTO 530 |

MOTO 630 |

|

1 Rullo sul piano |

1 Table roller |

|

|

|

|

2 Rulli sul piano |

2 Table rollers |

|

|

Standard |

|

Motore |

Motor |

HP (KW) |

10,0(7.5KW) |

10,0(7.5KW) |

|

Controllo elletronico di quota e di volocita |

Control electroinstallations and quota volocita |

MT/1' |

* |

Standard |

|

Rulli di traino gommati in uscita |

Feeding rollers rubber output |

|

* |

* |

|

Rullo dentato sezionato |

Sectioned feeding roller |

|

* |

Standard |

|

|

|

|

|

|

|

|