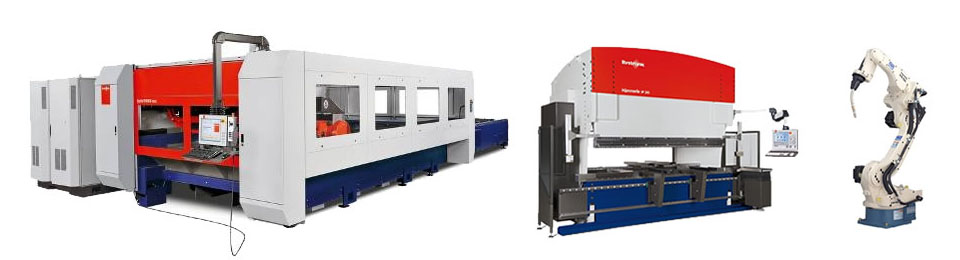

1- Sheet metal process

Our metal sheet is cut by imported laser equipment "Bystronic" and bended by CNC processing technology, which gurantee the machine with very good precision to be 0.1mm. Meanwhile it adopt Japan welding robot welding enclosure box, to ensure thebody is stable, strong, and fully welding. Benefit from the Italian design and technology, alll our machines use embedded methooand welding inside, it makes the machine has no welding outside, looks fantastic!

2- Processing

Using high-precision CNC machine to process eachcomponent, control the accuracy of each component, all theprecision machining make a good foundation for preciseassembly.

3- Final assembly and inspection

Italian headquarter MA CO.2L SRL dispatches experienced engineers and technicians to be stationed in Jiakemu all year round, responsible for process design and installation training. The technical personnel on the Jiakemu production line have an average of 10 years of production experience per person. Mature technology and rich production experience ensure that every SICAR product has reliable quality.

4- Packaging and Shipping

After strict inspection, all machines also need to undergo cleaning, rust prevention, and moisture-proof treatment. The equipment will be coated with CVI vapor phase rust prevention film and packaged in non fumigation plywood wooden boxes. Meanwhile, the outer box will also be wrapped with iron sheets and tied with fiber straps. All these comprehensive measures enable the machine to withstand long-distance sea and land transportation.

|